1. Disconnect and remove the old lead acid battery from your machine.

2. Run the wires from the battery compartment to where you are mounting the new battery information display (BDI).

3. Mount the BDI to your equipment using the provided hardware.

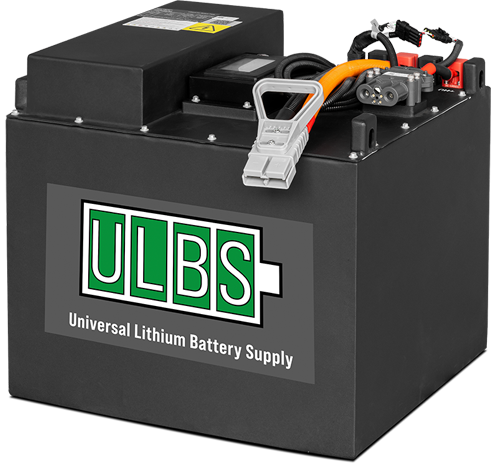

4. Place the new ULBS lithium-ion battery pack into your machine and attach the battery connector and the display connector to their respective connections.